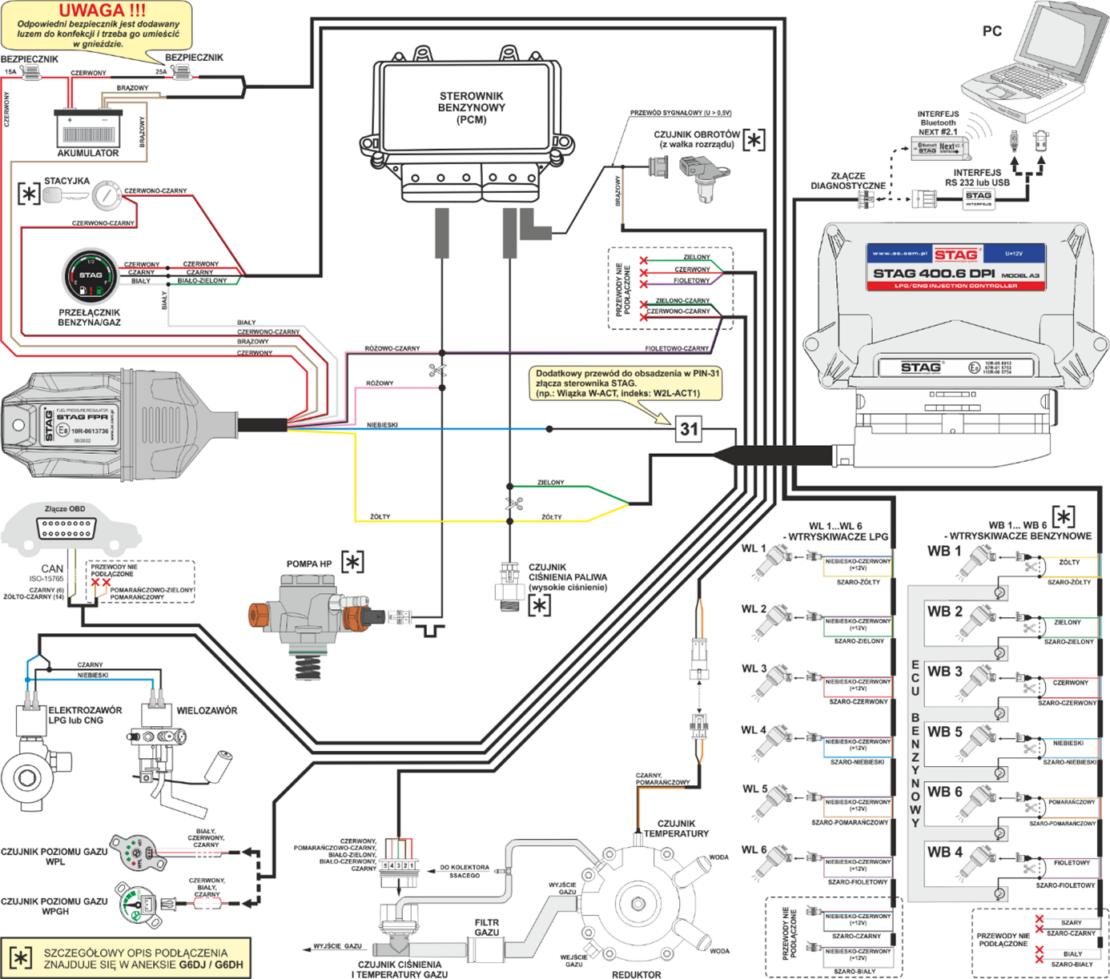

New STAG-400.6 DPI Model A3 controller

A new version of the STAG-400.6 DPI controller designated as model A3 is now available. Another STAG controller for six cylinders, in addition to the existing A1 and A2 (“EcoTec3”) models, has been adapted to the requirements of vehicles from the Hyundai/Kia group equipped with 3.3/3.8 GDI engines (supported engine codes are G6DH/G6DJ).

SHPAE and STAG FPR gasoline pressure emulation

The Hyundai/Kia G6DJ (3.8 GDI) and Hyundai/Kia G6DH (3.3 GDI) engine codes supported by the STAG-400.6 DPI A3 controller are the first to be made public, using an innovative way of gasoline pressure emulation. STAG High Pressure Advanced Emulation is an alternative to the classic STAG-400 DPI pressure emulation, which consists of:

- Proper pressure emulation implemented by the gas injection controller

- External device to prevent both overpressure and underpressure on the STAG FPR fuel rail

SHPAE uses a dedicated one-dimensional pressure emulation map representing a function in which the argument is the engine load and the values are the fuel pressure, expressed in [%] and [V], respectively. In fact, the engine load calculated by SHPAE is a virtual parameter that is a scalar derivative of the current state of the engine, such as RPM, high-pressure pump control, gasoline injection times, among others.

STAG FPR, i.e. a fuel pressure regulator, is an integral element of SHPAE because it eliminates the problem accompanying pressure emulation, i.e. its overshoot on the fuel rail due to the shutdown of gasoline injectors. In contrast to relays and fuel pump valve emulators, it also does not allow for its extreme reduction, thus preserving one of the basic functionalities of STAG-400 DPI, i.e. flushing of gasoline injectors (Note that dosing gasoline, e.g. using an extra share map at high loads is no longer feasible).

STAG FPR fuel pressure regulator

The STAG FPR controller is complete with a dedicated harness, and its coupling with the controller is carried out using the LED control panel cable. In the case of STAG controller, SHPAE requires an additional cable connecting it to the control of the high pressure fuel pump for operation.

The use of SHPAE emulation usually also results in lower gasoline consumption. However, this is a secondary result, related to the reduction in fuel rail pressure and the accompanying, usually lower cut-off value of the gasoline injector in the STAG configuration. Note that the primary rationale for SHAPE is the occurrence of destructive (limp mode-causing) pressure errors (e.g., P0088, P228D), which cannot be removed by using classic fuel pressure emulation and gasoline injector cutoff configurations.

The complexity of SHPAE emulation narrows the application of the new solution to selected engine codes. Nevertheless, it is planned to expand the range of codes supporting SHPAE and to expand it towards greater versatility.