STAG 400 DPI ULTIMUS

The new controller is the successor to the B3 model, and is thus the next development stage of the B-line controllers.

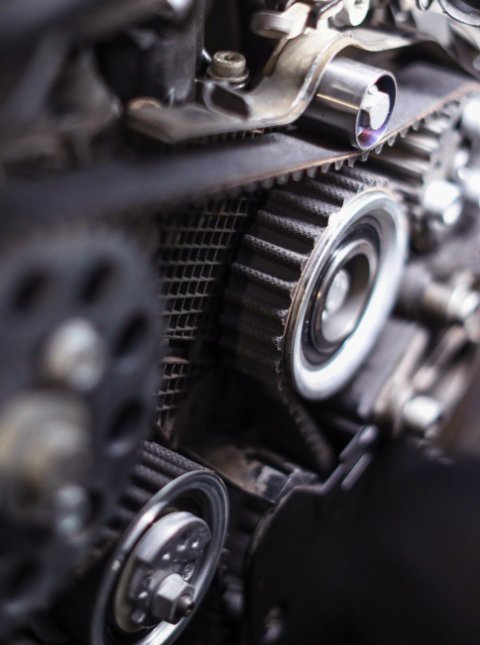

Modified input circuits for reading gasoline injection times

The most important change in this controller model is the modified input circuits for reading gasoline injection times, which are now immune to fluctuations in supply voltage.

More and more cars with variable battery power are appearing on the market. Instead of a constant supply from the alternator, the supply voltage varies depending on the load – both less and more. This means that the voltage can fluctuate significantly, even by several volts.

The fluctuating power supply poses several significant challenges for the installer. If the voltage was high during setup and then dropped while driving, the injection timing reading could fade or be disrupted. A disturbed injection timing reading prevents the controller from feeding fuel properly, resulting in jerking, misfires and/or misfires. In turn, the controller’s low-voltage configuration leads to an injector circuit error when the voltage increases.

STAG 400.4 ULTIMUS solves the problem of variable battery charging. The controller uses a new way of reading the injector circuit, operating according to a different logic than previous versions of the B line. In addition, a voltage stabilization circuit has been introduced, which maintains constant injection pulse reading conditions regardless of charging voltage fluctuations.

Ability to connect an external emulator

The second major difference is the ability to connect an external petrol injector emulator.

STAG 400 DPI controllers operate according to the logic of regulating gasoline combustion in favor of gas, mainly through the configuration of the so-called injector cut-off. The injector flow is closed earlier or later to reduce gasoline combustion. The opening time of the gasoline injector should be as short as possible so that as little of this fuel as possible enters the combustion chamber. In some systems, any attempt to cut off the injector more forcefully resulted in immediate errors from the car’s fuel computer and consequent permanent shutdown of the injectors. This was a significant barrier to the conversion of such engines.

To solve this problem, an external emulator was needed. Not the passive one known from indirect injection technology, but one that is synchronized with the gasoline controller. STAG 400.4 DPI ULTIMUS is equipped with additional outputs, necessary for connecting an external emulator. This is an important design change, which will allow to flexibly expand the controller’s functionality in the future, following the development of modern gasoline engines.

Second independent CAN interface

The standard – so far used in STAG controllers – was a single CAN interface, used for connection with the so-called generic OBD (EOBD/OBD2). However, the commonly used OBD2/EOBD-compatible solutions allow reading only standardized parameters. Meanwhile, car manufacturers use dedicated, more complex OBD communication channels in parallel, offering more possibilities.

In the STAG 400.4 DPI ULTIMUS controller, we have added a second physical CAN channel, independent of the existing one, allowing the controller to be coupled to a second vehicle bus. For example, one that is compatible with the so-called ISO/TS.

We used this functionality to create SX OBD (STAG EXTENDED OBD). We use it in vehicles with the Puretech 1.2 engine code, for which we developed an electronic fuel level emulator.

How it works?

In some car models, the fuel level is not measured, but calculated. This is particularly popular in car models from French manufacturers and related co-ops, such as Citroen Berlingo and Toyota ProAce. The car does not just read gasoline consumption from a sensor mounted in the tank called a float, but calculates it numerically based on gasoline injection times. This generates significant challenges when converting to LPG. When driving on gas power, the gasoline controller reads the injection times and estimates gasoline consumption based on them. The result? The gasoline consumption indicator drops even though the tank is full of gasoline. Turning off the ignition has no effect. With SX OBD, this type of problem can be easily solved with a digital command sent to the vehicle’s controller. Until now, an additional external fuel level emulator, attached to the relevant vehicle harness wires, was needed to solve this problem.

This is a simple example that illustrates the capabilities and potential of this solution. When the need for additional digital emulation arises, the modified design of the controller provides this possibility.

Added value – digital emulation is much less labor-intensive. It does not require dismantling thresholds, cutting circuits or soldering. Currently, the process has been reduced to plugging the CAN communication wires into the OBD connector.